Allgemeine Richtlinien zur Nutzung

Ein Minimum 100 Tonnen-Kran benötigt, um die Lastkähne vom LKW auf das Wasser weg zu laden. Each barge has a single lifting clevis or shackle in the top of the barge for easy loading and unloading. Poseidon® 1 -10’ x 40’ x 5’ barges weigh 23,500 lbs. Poseidon® 2 -10’ x 40’ x 5’ Sectional Barges weigh 23,700 lbs. each and Poseidon® 3 Barges weigh 23,700 lbs. each. Tag lines should be attached to the ends of the barges to control the movement of the equipment while in the air. After pulling the barges together, have a couple of men stand on the outside of the barges in order to cause the barge to come together at the bottom. An alternate method is to thread a small choker through the rope thimbles on both barges and lift up slightly with the crane. Once the bottom is together, carefully drop the 55 lb. pin in place being careful not to pinch your fingers.

The Poseidon® 1

barge has a Rendrag® compatible connection system. Hairpin connectors are dropped into position. The 40’ x 10’ x 5’ barges are equipped with 8 connection points on the sides and 2 connection points on the end. Each 40’ x 10’ x 5’ barge can support 35,000 lbs at a 2’6” draft. Rope thimbles on the sides and ends of the barges are used to assist in pulling the barges together prior to pinning.

The Poseidon® 2

barge has a Flexifloat® compatible connection system. The internal locking clasp is pried up with a lifting bar. The barges are pulled together using ropes in the rope thimbles. An alternative method would be to run a small choker through both rope thimbles and lift up slightly with the crane. This will draw the bottom of the barges together. The barges need to be near touching before the locking bar will drop down at the top or the bottom. The locking clasp may be tapped into the locked position with a small hammer.

The Poseidon® 3

barge is Shugart® compatible. The P3 barge has a set of upper and lower angles on the sides and ends of the barge. There are 32 pin holes on the 41’4″ length and 8 pin holes on the 10’4″ end. The P3 barges must be assembled so that the narrow side angles fit above and below the wider side angles on he opposing barge. Line up and secure the pin on the end of the barge, then fold the barge together against the opposing barge, drop the pins into the angles beginning at the opposite end.

Use of Hardwood Mats on Poseidon Barges

The contractor must supply and use oak or yellow pine 8" - 12" crane mats when using cranes, excavators or any other pieces of equipment with steel crawler tracks or rubber tire equipment. Below are examples of damage that has occured to barges when they are not used properly. The sides, ends& bottom skin surface of the barge is made of A-36 1/4” steel plating. The tops are covered with a skid resistant 11 gauge patented roll form material. Damage to the barges on the project will be repaired and invoiced back to the contractor. Pictures of the damages will be taken along with an estimate of the repairs prior to the work being completed for the contractor’s review. Below is a sampling of pictures from damaged equipment returned after the project.

DAMAGE:

Any defect that structurally impairs or degrades the equipment in its ability to perform the intended function and duty including, but not limited to, providing flotation for construction equipment. Or, any defect that materially degrades the commercial resale value of the equipment, beyond an amount typically expected based upon the duration, duty cycle, and type of work performed during the rental period.

Specific Damage Criteria for Equipment Sides, Ends, Decks, or Bottoms:

- Any structural member deformed by ¼” or greater. (Angle, channel, formed pocket, casting, rope thimble)

- Any plate section deformed by ½” or greater, regardless of size of defect

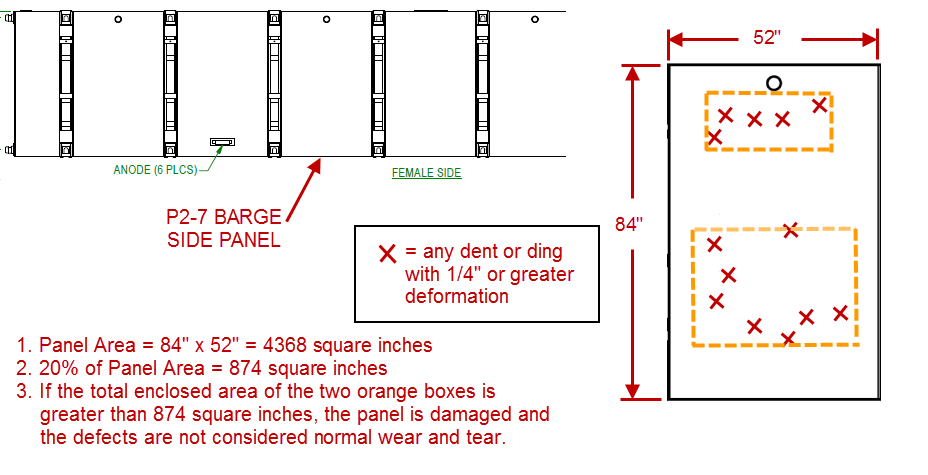

- Any plate section deformed by ¼” or greater when defect distribution is 20% oder mehr des Paneels quadratische Fläche. (Siehe Abbildung unten).

- Jedes Loch oder Riss in dem Stahlmaterial durchstochen wird, gilt als Schaden.

BEISPIEL SCHÄDEN Assessement BERECHNUNG: 20% PANEL BEREICH REGEL

Beispiel Bilder und Zeichnungen SCHADEN

Gerollte Tops oder Waschbord tritt als Folge von nicht Holz Matten unter Verwendung. Beschädigte Ecken und Endwandflächen auftraten, wenn die Seiten und Ende des Lastkahns mit einer Baggerschaufel oder mit dem Druck Knien des Schleppers getroffen wurden. die Spitzen, Seiten und Enden dieser Kähne wurden ersetzt und die Kosten wurden an den Auftragnehmer weitergegeben. Die Außenplatte ausgeschnitten ist und zusammen mit Innenwinkeln und beschädigt Struktur entfernt. Ersatzteile werden an Ort und Stelle geschweißt, coated with bio-float rust inhibitor on the interior and the exterior is blasted and painted with a Baril Zinc Rich Urethane primer and a low gloss Aliphatic Polyuria finish.Sobald Ihre Betreiber die Seite des Lastkahns mit der Baggerschaufel oder einem Stein oder einem anderen schweren Trümmer treffen fällt auf dem Kahn Deck verursacht eine Delle, sofort stoppen, fotografiere des Schadens, Dokumentieren Sie Datum und Uhrzeit des Vorfalls und melden Sie den Schaden Ihrer Versicherung. Sie müssen ein bestimmtes Datum angebenf Schadensfall an den Versicherer zur Deckung des Schadens.Der Bediener sollte in der richtigen Verwendung der Ausrüstung geschult werden, damit sich der Schaden nicht wiederholt. Auch benachrichtigenPoseidon® Lastkahn des Schadens.

Der Auftragnehmer verschweißen kann zusätzliche Winkeleisen, Schellen, etc. um jegliche Ausrüstung auf den Kähnen zu sichern.Poseidon® Barge verlangt, dass diese Gegenstände entfernt und verbleibende Fragmente auf die ursprüngliche Oberfläche abgeschliffen werden, bevor das Barge am Ende der Mietzeit zurückgegeben wird. Besprühen Sie den Bodenbereich mit Red / Brown Rustoleum Farbe.

Spuds und Taschen sind vorhanden, um die Barge in Position auf dem Wasser zu sichern.Spuds should be supported by two chokers or nylon straps rated to lift 10,000 pounds or more prior to the truck driver removing the chains or straps securing the spuds to the truck bed. Dadurch wird sichergestellt, dass sie rollen nicht oder LKW abrutschen erwartungs. Spuds sind in die Bodenfläche des Sees abgesenkt, Teich oder Fluss und unten in den Schlamm gedrückt. The barges can also by tied off by rope or cable through the thimbles on the sides or ends of the barges or by using the cleats supplied by Poseidon® Barge.

Do not pound on the top of the spud with an excavator bucketas this will damage the spud. Repairs to the spud due to such activity will be charged back to the contractor. Spuds can be raised and lowered by a crane line or by a hydraulic winch. Poseidon® Barge offers double drum winch units for sale or for rent. 5/8” Steel cable is tied off on the outside of the spud pocket on the lifting eye, threaded through the 20” sheave at the bottom of the spud and then brought up through the spud pocket and attached to the winch. If you run steel cable from the barge or winch across the body of water you are working on to the shore, bright orange vinyl ribbons should be hung from the cable, making it visible to any water craft that is operating in the vicinity.

Rental Rates do not include insurance on the barges. A Certificate of Insurance naming Poseidon Barge, Ltd as “Additional Insured” under your general liability policy, plus listing us as a “Loss Payee” under your equipment floater policy for dual protection against physical damage must be supplied, prior to shipping the barges to your job site. Additional details and requirements are included with our quote and lease agreement.

Adequate trainingfor operating the equipment, transported and used on the barges is the contractor’s responsibility. Poseidon® Barge, Ltd are not liable for any accidents due to operation of equipment on the barges under any circumstances including unsafe weather conditions, such as high winds, thunder storms, heavy rains, high wake, and icy or heavy snow conditions or any other hazardous weather conditions. Normal loading, unloading, dredging processes, and high humidity in the air may cause water to pool on all working surfaces on the barges. Care must be taken by equipment operators and workers to ensure the safety of the workers and equipment. Life vests should be worn at all times when working around the water. In sub-freezing air temperatures, ice will form on the barges and crane mats. It is the contractors responsibility to take any and all precautions in safe guarding their employees as well as the general public.

Minimum width necessary to float equipment.Poseidon® does not recommend floating a 25-30 ton excavator on a platform less than 30′ wide (3 sections 40′ x 10′ x 5′ wide). Additionally, if you are performing dredging work in hard digging conditions, Poseidon® also recommends a minimum of 4 spuds and pockets to minimize possible damage to the spuds & pockets as a result of the pulling energy caused by the bucket in hard soil conditions. If the contractor observes that Poseidon® equipment is getting dented up, spud pockets are being pulled apart, and or spuds are getting bent as a result of the excavator being too large for the platform, soil conditions are too hard or the operator is using the equipment in a careless manner, it is the contractors responsibility to change the parameters of the project and find an alternative method to complete the project. The contractor is responsible for all damages to the equipment. Just because our barges will float your equipment does not mean they can withstand the additional abuse as a result of difficult & hard digging conditions.

Poseidon® Barge offers static stability analysis for the use of floating cranes. Our analysis is only as good as the information provided. Knowing the make and model of the crane, die Länge des Auslegers, der Radius Sie mit dem Kran arbeiten wird, das Pick Gewicht und das Gewicht und Art der zusätzlichen Ausrüstung, die auf dem Kahn unsere Mitarbeitern helfen wird floating richtige Empfehlungen zu machen.

Vor der Ausrüstung auf die Rückkehr, Alle marinen Bewuchs und Schmutz müssen von den Lastkähnen gereinigt werden.Bewuchs umfasst Seepocken, bryozoans, Mollusken, polychaete und anderes Rohr worms, Zebramuscheln, Seetang, Algen & anderer Schmutz oder Schlamm auf der Barge Oberfläche. Möglicherweise müssen Sie die Lastkähne abkratzen und anschließend dampfreinigen, um das restliche Material auf dem Lastkahn zu töten. ObPoseidon® muss das Gerät neu reinigen, die Reinigungskosten werden den Auftragnehmer in Rechnung zurück.

Ballastwasser und Wasser, das sich durch Kondenswasser ansammelt, müssen von den Lastkähnen entfernt werden, bevor sie aus dem Wasser gehoben und auf den LKW geladen werden.Wasser im Inneren des Lastkahns führt zu Übergewicht der Ladung. Der Lastkahn wird nicht gleichmäßig aus dem Wasser gehoben, da sich in der oberen Mitte des Lastkahns ein einziger Hebepunkt befindet. Ebenfalls, Wenn der Fahrer schnell anhalten muss, kann das Verrutschen von Wasser innerhalb des Lastkahns dazu führen, dass sich der Lastkahn auf dem LKW verschiebt. Wasser kann mit einem Luftkompressor und den Wasserballaststopfen an den oberen Ecken des Lastkahns ausgeblasen werden. It can also be pumped out or if necessary, cut a 2” hole on the sides of the barge towards the end approximately 3” from the bottom to drain the water out prior to shipping. Please notify us when doing this, so that we can anticipate the repairs. The Poseidon® Barge system is designed for easy handling and economical transportation to and from your project.

Poseidon® Double Drum Winch: Daily maintenance and inspections should be done to assure safe operation. Oil levels should be checked daily. The key is located on the dip stick when you first receive the unit. The engine should be started and allowed to idle for a minimum 30 minutes to allow the hydraulic oil to heat up. Operating hydraulic equipment with cold hydraulic oil could cause seals to break resulting in hydraulic oil spills. We use 46 weight Clarity Oil in our equipment to minimize environmental impact. Wire cable is not supplied by Poseidon® with the winch. All cable is to be removed prior to returning the winch and the fuel tank should be filled up. Tape the wedges to the drums using duct tape.

Poseidon Sea Bees: Daily maintenance and inspections should be done to assure safe operation. Oil levels should be checked daily. The units should be started and allowed to idle for a minimum of 30 to 90 minutes to allow the hydraulic oil to heat up depending on the air temperature. Oil levels should be checked on a daily bases. Hoses should be visually check to assure that there are no kinks or leaks in the hoses. If you hit the propeller on a rock or tree, stop the unit immediately and inspect the prop for any damage. This may cause the seal in the hydraulic motor in the prop housing to break or bend the shaft on the propeller. If this occurs, the 8″ steel tube shaft will fill up with hydraulic oil. If you notice oil leaking out of the top of the steel shaft, shut down the unit immediately and call Poseidon® to make arrangements for a repair.

Winch Units & Barge Pusher Units should be secured with four long chokersan den Halterungen an den Rahmen der Einheiten befestigt und durch das Kranseil gestützt, bevor der LKW-Fahrer die Ketten oder Gurte entfernt, die die Einheiten am LKW befestigen. Dadurch wird sichergestellt, dass die Geräte nicht verschieben oder fallen erwartungs den LKW Schäden an der Ausrüstung oder Verletzung Bodenpersonal verursacht. Die Geräte müssen Niveau bleiben, wie sie aus dem LKW gehoben werden.